The Walloon aeronautics industry employs over 5,500 people with a turnover of 1,350 million euros.

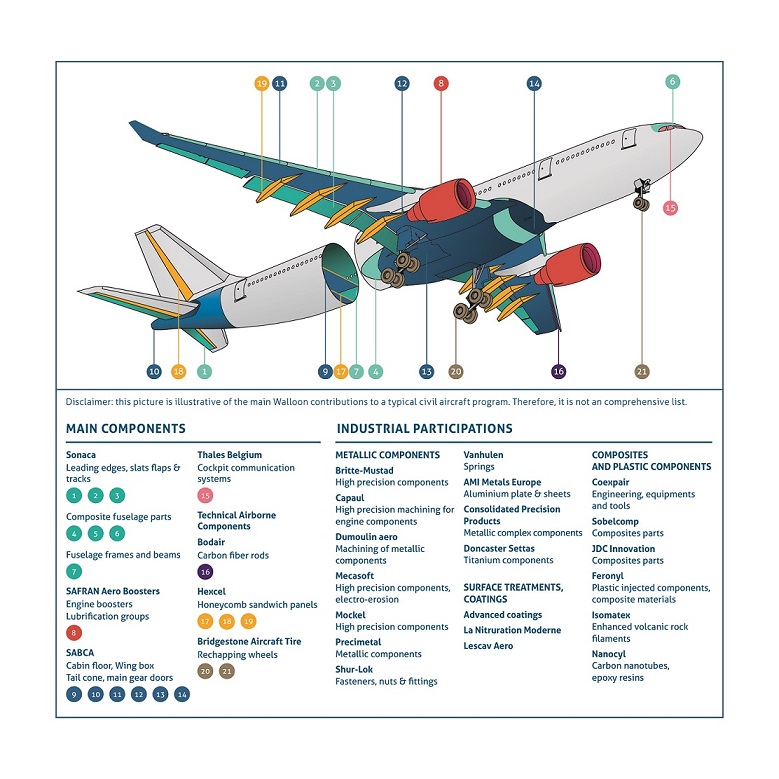

The activity is focused on the following area:

- structures

- aircraft engines

- engine test benches

- embedded systems

- maintenance and repair (MRO)

- simulation and assisted design

- airport services

- R&D

- training